Buy favorable price 2 in. 2 way union air actuated PVC ball valve with pneumatic actuator online. Compact full port pneumatic plastic ball valve has such advantages as small fluid resistance, simple structure, small in size and light in weight. Our ball valve is made from high performance PVC material, allowing it to service different medium from low to high temperature. It is widely used for water, oxygen, gas, nitrogen gas, gasoline and other air and fluid control.

Specification

| Model |

T-PBV-50A |

| Power Source |

Compressed Air |

| Actuator Type |

Double Acting |

| Ball Valve Type |

2 Way |

| Port Size |

2 inch (DN50, 50mm) |

| Bore Size |

75mm |

| Pressure Range |

<=1000PSI (6.9MPa) |

| Air Pressure |

0.3 - 0.8MPa |

| Air Supply Port |

1/4 inch |

| Environment Temperature |

-10 °C to 60 °C |

| Medium Temperature |

UPVC: -10 °C to 45 °C, CPVC: -15 °C to 90 °C |

| Medium Pressure |

1.6MPa |

| Seat Material |

Plastic (PTFE) |

| Ball Valve Material |

PVC/UPVC/CPVC |

| Actuator Body Material |

Aluminium Alloy |

| Applicable Medium |

Water, Air, Hot Water, Steam, etc. |

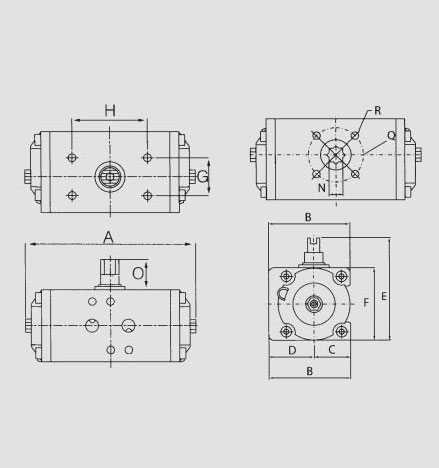

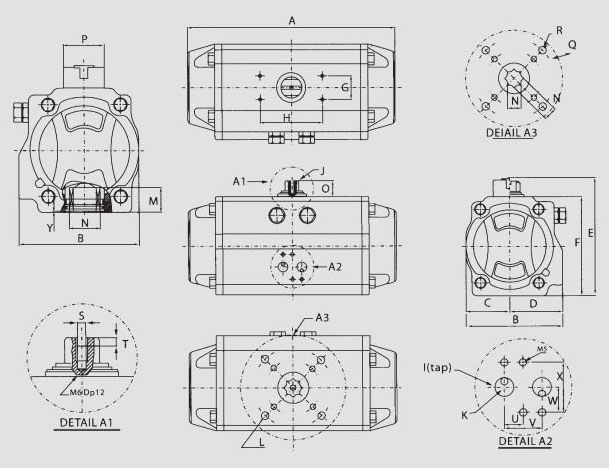

Pneumatic Actuator Dimension

|

|

Q: Φ50/Φ70mm

A: 213mm

B: 93mm

C: 42.5mm

D: 50.5mm

E: 130mm

F: 102mm

G: 30mm

H: 80mm

I: PF

J: M6

K: 1/4"

O: 20mm

P: 40.5mm

S: 4mm

T: 4mm

U: 12mm

V: 24mm

W: 16mm

X: 32mm |

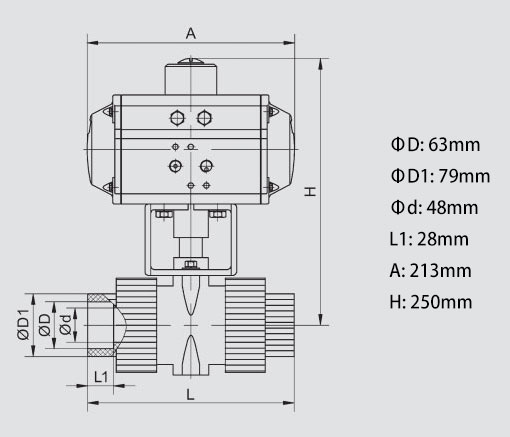

Body Dimension

Tips: Different Types of Pneumatic Ball Valve

There are a lot of types of pneumatic ball valves, according to its channel position can be divided into straight way, two way, three way and right angle. Because of the advantages of compact structure, easy operation and maintenance, it has been welcomed by many users. Here are the types of the air actuated ball valve.

1. Floating ball valve. The ball of the pneumatic ball valve is floating, under the action of medium pressure, the ball has a certain displacement and press the sealing surface of the outlet to ensure that the outlet end is sealed. The floating pneumatic ball valve has a simple structure and good sealing, but the ball transfers all the load of working medium to the outlet sealing ring, therefore, it is necessary to consider whether the sealing ring can work under the medium load. This structure is widely used in low and middle pressure ball valves.

2. Fixed ball valve. The ball of the pneumatic ball valve is fixed and does not move under the medium pressure, but it comes with the floating valve seat. When it gets the medium pressure, the valve seat will move to help the sealing ring press tightly on the ball. Bearings are usually mounted on the upper and lower shafts of the ball valve, with small operating torque. Some fixed pneumatic oil sealing ball valves emerge in order to the operating torque of pneumatic ball valve and increase the reliability of sealing. They are more suitable for high pressure large diameter applications.

3. Elastic ball valve. The ball of the pneumatic ball valve is elastic. The ball and the seat sealing ring are made of metal. It will not reach the requirement of sealing depending on the pressure of the medium itself, so it must apply external force. This pneumatic ball valve is suitable for high temperature and high pressure media. The elastic ball obtains elasticity by cutting an elastic groove at the bottom of the inner wall of the ball. When closing the channel, use the stem wedge inflate the ball, making it press tightly the seat. Loosen the wedge before turning the ball, and the ball returns to its original shape, creating a small gap between the ball and the seat to reduce friction on the sealing surface and operating torque.