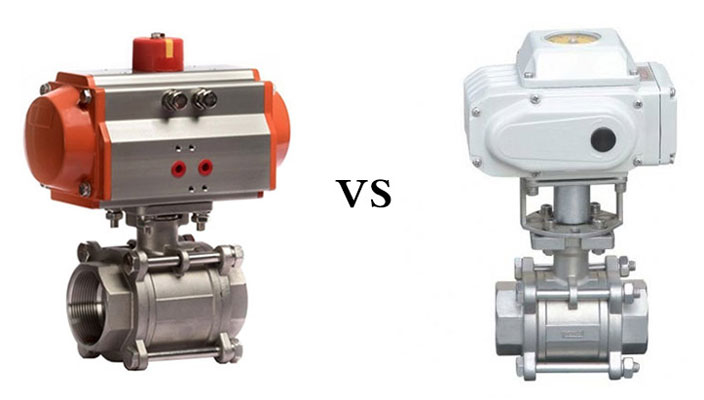

What is the pneumatic ball valve?

Pneumatic ball valve is a ball valve with pneumatic actuator. It is a kind of automatic equipment that drives the ball valve to open and close by the compressed air, complete the switching and conditioning of the medium, and then reach the switching or conditioning intention of the pipeline medium. Pneumatic ball valves are generally equipped with various accessories, such as solenoid valves, air source treatment triples, limit switches, positioners, control boxes, etc., to complete local control and remote centralized control. The valve can be switched on and off in the control room. There is no need to go to the scene or high altitude and bring manual control at risk, which greatly saves manpower and safety. There are different types of pneumatic ball valves, including stainless steel pneumatic ball valve, plastic pneumatic ball valve, sanitary pneumatic ball valve, carbon steel pneumatic ball valve, 2 way pneumatic ball valve, 3 way pneumatic ball valve, etc.

What is the electric ball valve?

Electric ball valves are generally connected by electric actuators and ball valves. After debugging through the device, it will become an electric ball valve. The electric ball valve uses electric energy as power to turn on the electric actuator to drive the ball valve, complete the switching and conditioning actions of the ball valve, and then reach the switching or conditioning intention of the pipeline medium.

Pneumatic ball valve vs. electric ball valve

- Pneumatic ball valve has a larger force than electric ball valve. The opening and closing action and speed of the pneumatic actuated valve can be adjusted. Its structure is simple and easy to protect. Due to the cushioning characteristics of the gas itself, it is not easy to be damaged due to jamming during the operation. However, it needs a gas source, and its control system is more complicated than an electric valve. The pneumatic ball valve is flexible, safe and reliable. Many places with high control requirements set up compressed air stations for pneumatic exterior control components. The power source of the pneumatic actuator is the air source, and the positioner is used to convert the electric control signal into the pneumatic control signal, and the pneumatic actuator is driven to adjust the valve position.

- The power source of the electric valve actuator is the power supply, and its circuit board or motor is prone to sparks, so it is generally used in places with low environmental requirements and no risks.

- The pneumatic ball valve is faster than the electric ball valve. Under normal circumstances, the opening and closing time of the pneumatic ball valve is about 6 seconds, while the opening and closing time of the electric ball valve is generally 15-20 seconds.

-

The essential difference between electric valves and pneumatic valves is the use of different actuators. Generally, different actuators are selected according to the requirements of working conditions. For example, in the chemical industry and other occasions that require explosion protection, pneumatic valves are most used, because it is cheap and convenient to operate. It also has intelligent locator which meets high safety requirements.

-

Electric ball valve advantages: It has a good effect on liquid media and large-diameter gas, and is not affected by the weather or the pressure of compressed air. Disadvantages: high cost, poor performance in humid environments.

-

Pneumatic ball valve advantages: It has a good effect on gaseous media and small diameter liquids, low cost and convenient protection.

In general, pneumatic ball valves are superior to electric ball valves. The electric ball valve has fast action and is suitable for use in places where there is no external gas source, but its safety function is poor, and it is not easy to be used in flammable and explosive places with high explosion-proof requirements. During operation, the performance of electric ball valves is not as stable as pneumatic ball valves, and the cost and maintenance costs are high. However, the pneumatic ball valve can fully meet the control requirements, and the device is easy to use. Its safety function is relatively high, and it is suitable for places with high explosion-proof requirements such as inflammable and explosive. Tool.com provides 1/2”, 1”, 2”, .... pneumatic ball valve for your choice, they are all at best price, shop online now!