Rebar Tying Machine

Automatic Rebar Tying Machine, 18V, 4-28mm

Automatic Rebar Tying Machine, 18V, 4-45mm

Automatic Rebar Tying Machine, 18V, 4-58mm

Automatic Rebar Tying Machine, 14V, 12-60mm

Automatic Rebar Tying Machine, 14V, 4-28mm

Automatic Rebar Tying Machine, 14V, 6-40mm

Automatic Rebar Tying Machine, 9V, 4-28mm

Automatic Rebar Tying Machine, 9V, 6-45mm

Automatic Rebar Tying Machine, 9V, 12-58mm

Best automatic rebar tying machine for sale, with good price and high quality. Automatic rebar tying tool is a kind of hand-held battery high-speed steel bar binding tool, which is used for tying steel bars, round pipes, heating floor meshes, etc. It is powered by lithium battery or NI-MH battery. In our rebar tiers, you can select battery voltages 9V/14V/18V. Applicable steel bar diameters are available in 4-28mm/ 4-45mm/ 4-58mm/ 12-60mm/ 6-40mm/ 6-45mm/ 12-58mm. The efficiency of automatic rebar tier is 3-4 times of the labor efficiency, which can save a lot of manpower and greatly reduce the labor intensity of workers. It is convenient and our price is affordable.

Automatic rebar tying machine

Automatic rebar tying machine is a hand-held machine for automatic steel tying, also known as the rebar tier, which is a new type of intelligent power tool for steel construction. The automatic rebar tying machine has a beautiful and practical appearance and a built-in microcontroller, which can automatically complete all steps of reinforcing steel strapping. It is widely used in construction sites, large bridges, roads, railways, tunnels and other large projects, and can completely replace the manual tying of reinforcing steel bars. It is the first choice tool for reinforcing steel strapping in construction sites at present. The characteristics of automatic rebar tier are fast, convenient, safe and reliable, simple operation, and greatly reduce the labor intensity. The rebar tying machine is shaped like a large pistol. There is a wire winding mechanism at the muzzle, a rechargeable battery is installed at the handle of the gun, the tail of the gun is equipped with a coil to supply the muzzle wire, and the barrel is equipped with a transmission rotating device and the power distribution device, the trigger is the power switch.

Features of the rebar tying machine

- Small size and light weight.

- Efficient and fast, one machine can replace 3-5 traditional wire tie workers.

- Spinning is stable, and the success rate of wire binding can reach more than 99%.

- Intelligent automatic, automatic wire feeding, winding, twisting, cutting and unhooking.

How to use rebar tier?

Charging batteries

- Charging must be carried out in a cool and dry indoor environment.

- This product needs to be charged with a dedicated charger.

- Before charging, you must check the wires and the appearance of the case for damage.

- The medium and high-end batteries are charged with designated battery adapters.

Bundling operation

- Check the host and its components to ensure that they are in good condition and installed in place.

- Press the switch button to turn on the power.

- The battery indicator lights up, changing from red to green, accompanied by a beep.

- Bite the muzzle of the gun at the center of the intersection of the steel bars to make it completely inside the muzzle. It is suggested that the gun body and the reinforcement form a 90° angle (i.e., the gun body is perpendicular to the reinforcement surface), and the gun head should not press on the reinforcement. On the premise that the iron wire hoop can enclose the cross reinforcement, the spinneret at the gun tip should be close to the lower reinforcement as far as possible.

- Press the trigger, the machine will automatically bind, and when the thread mechanism stops and reset, the binding is completed.

- After the strapping is completed, move the machine forward and upward to separate it from the strapping wire knot.

Installation of wire reel

- Press the "lock trigger" and the "back cover" will automatically open.

- Load the wire reel.

- Press the "lock button" to fix the wire reel.

- Manually thread the iron wire until it meets the requirements. (when manually threading the iron wire, press the "clutch" button, check through the window on the top of the body, and let the iron wire pass into the cone sleeve through the middle of the gear set.)

- Close the back cover.

How does a rebar tier work?

- Using the technological breakthrough of the two-signal single-motor system in the work of the automatic rebar tier, the five processes of spinning, winding, winding, tightening and cutting during the steel tying process are realized.

- Utilizing the high-tech electronic control system of the rebar tier machine open and fork-shaped twisting head, the wire feeding length and tightening process of the machine are just right, and the automatic control of the tightness of each rebar tying joint is realized.

- The use of the automatic steel tying tool to simplify the efficient transmission system, the machine is small in size, light in weight, and flexible in operation, ensuring the practicability and safety of the automatic steel tying construction process.

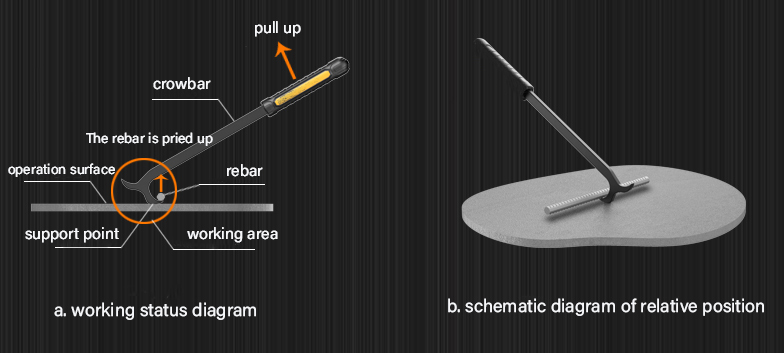

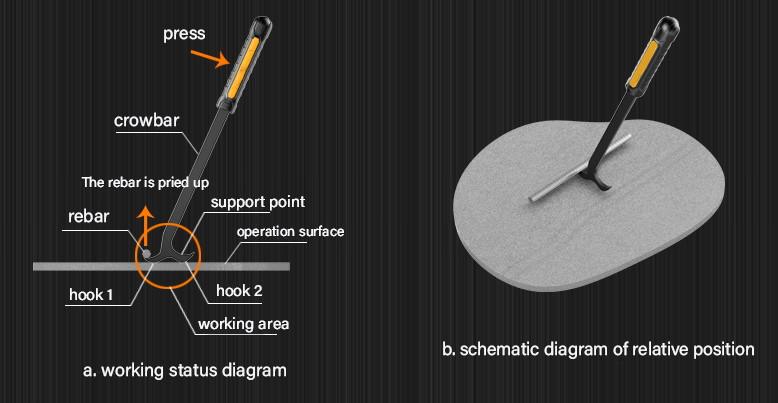

The use of pry hook

There are two hooks on the hook body of the pry hook, forming an "r"-shaped structure. The hook can be inserted between the steel bar and the template, and the steel bar and the template can be pulled a sufficient distance, so that the rebar tier can operate smoothly. Choose the method of prying steel bars according to your habits and environment.

Method 1: Insert "hook 1" into the bottom of the steel bar to be pryed, and use "hook 2" as the support point. Press the handle in the direction of the arrow to pry the steel bar off the ground and perform the steel bar bundling operation.

Method 2: Insert "hook 2" into the bottom of the steel bar to be pried, and use the back of "hook 2" as the support point. Pull the handle in the direction of the arrow to pry the steel bar off the ground and perform machine bundling operations.

11 tips for using rebar tier safely

- When the power of the rebar tier is low, the power indicator will be red and the rebar tier will stop working.

- The remaining amount of iron wire can be observed through the back cover during use.

- There should be no obstruction between the bottom of the guide wire and the wire outlet.

- If the iron wire remains inside the cutter body, it can be taken out with a tool through the top window of the rebar tier.

- After the installation of the wire tray, the wire head may be irregular, which may lead to poor binding for the first time. It is suggested that after the installation of the wire, the wire should be put into use again after trial operation.

- It is forbidden to put your hands in or near the twisting area.

- When the strapping process is not completed, please do not pull out the rebar tier to avoid bad strapping.

- If the wire knot remains in the gun head after the binding, please take it out and proceed to the next operation.

- When the wire reel is exhausted, be sure to pull out the remaining wires along the plastic wire reel. Do not cut the wire directly, otherwise the rebar tier will be blocked by the wire and cannot work. If the wire cannot be withdrawn, first check whether the scissors head is tight. If it is tight, use diagonal pliers to turn the torsion shaft a few times to withdraw smoothly.

- There is a running-in period when the new rebar tier is used, and the wire may not be wound tightly. This is a normal phenomenon, and it will become tighter in a short time. In addition, the new battery is dead or insufficient, and there is also a phenomenon that the wire is not tightly wound. This phenomenon will be eliminated by replacing the fully charged battery. Please rest assured to use it.

- The new battery should be used up first, and then fully charged again, so as to extend the battery life and better serve you.