17 Feb 2021

How to Use a Laser Level?

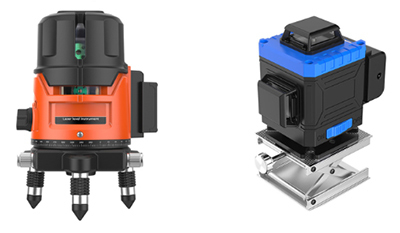

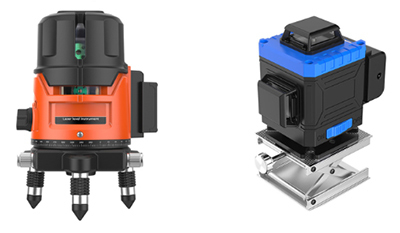

The laser level is widely used in the construction industry, is a measuring machine for measuring the level. It has the advantages of high accuracy, convenient use, fast and reliable, and can be used in surveying, large-area site surveying, floor level marking, settlement observation, etc. Tool.com will explain in detail the operation and control steps of the laser level for wholesale online.

1. Open the tripod, keep its height near the chest, keep the head of the frame roughly level, step on the toes into the soil, and then use the connecting screw to connect the equipment to the tripod.

2. First of all, we must understand the names and functions of the parts of the laser level and be familiar with their use. The laser line meter is made by fixing a laser device on the tube of an ordinary level telescope. The laser device consists of a nitrogen-neon laser and a prism light guide system.