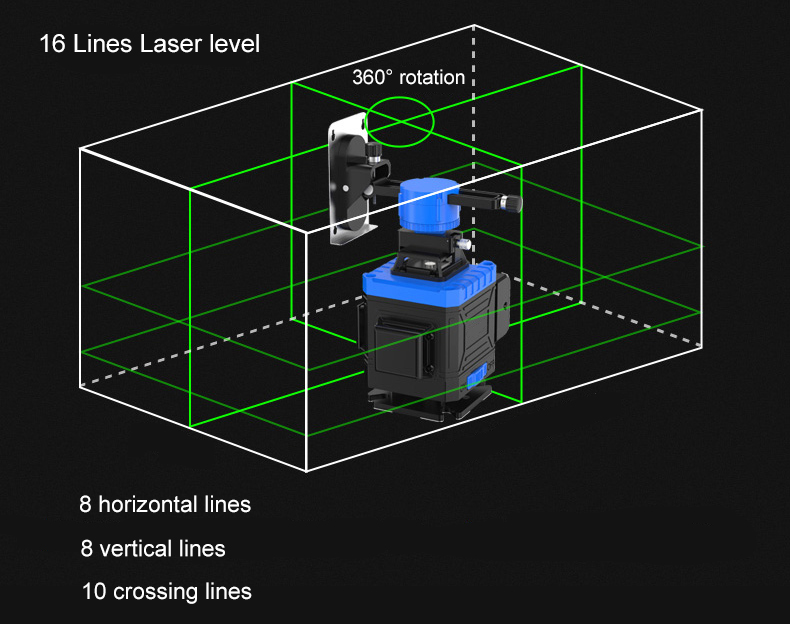

16 line green laser level tool automatically self leveling at ±3°, 8 vertical line and 8 horizontal line, allowing 360° free rotation of the laser level and projection of the laser line at any position or angle. Best for floor tiles, doors and windows, furniture woodworking installation, wallpaper hanging, drilling applications.

Specification

| Model |

T-SL-16 |

| No.of Laser Lines |

16 |

| Leveling Type |

8 vertical line, 8 horizontal line, 10 crossing line |

| Laser Wavelength |

635nm |

| Self-Leveling Range |

±3° (when angle of inclination ≤3°, laser level auto self-leveling; when angle of inclination ≥3°, buzzer alarm.) |

| Launch Angle |

≥120° |

| Horizontal Accuracy |

5m±1mm |

| Vertical Accuracy |

5m±1mm |

| Plumb Dot Accuracy |

±1mm at 1.5m |

| Line Width |

1.5mm |

| Line Color |

Emerald green |

| Power Source |

Lithium battery / DC charger |

| Battery Type |

2 x 5800mhA rechargeable lithium battery (72 hours standby) |

| IP Rating |

IP 54 |

| Operation Temperature |

-10℃~50℃ |

| Wall Distance |

7mm |

| Ground Distance |

6mm |

| Function Key |

Fingerprint touch buttons |

| Laser Head |

Made in Germany |

| Material |

Alloy body + plastic shell |

| Working Time |

12 hours |

| Remote Control |

Yes |

| Slash Mode |

Yes |

| Application |

Ceiling, home decoration, door and window installation, etc |

| Weight |

3kg |

| Packing Included |

1 x 8 Line Green Laser Level

2 x 5800mA Lithium Battery

1 x Power Adapter

1 x Magnetic Bracket

1 x Adjustable Lifting Platform

1 x Magnetic Pivoting Base

1 x Hand-shell Carrying Case

1 x Remote Control

1 x Conversion Screw

1 x User Manual |

Details

Tips: How to measure verticality with a laser level?

When measuring the verticality of large parts, use a level to roughly adjust the reference surface to a horizontal position. Use a level to measure step by step on the reference surface and the measured surface, and use the graphic method to determine the reference orientation, and then calculate the perpendicularity error of the measured surface relative to the reference.

When measuring the verticality of small parts, first place the laser level on the reference surface, read the value of one end of the bubble, and then use the side of the laser level to stick to the surface to be measured. The first reading value of the bubble deviation from the reference surface is The verticality error of the measured surface.

When using a laser level meter, ensure that the working surface of the laser level meter and the surface of the workpiece are clean to prevent dirt from affecting the accuracy of the measurement. When measuring the horizontal plane, in the same measuring position, the level should be adjusted to the opposite direction before second measuring. When moving the level, the working surface of the level is not allowed to rub against the surface of the workpiece, and it should be lifted and placed.