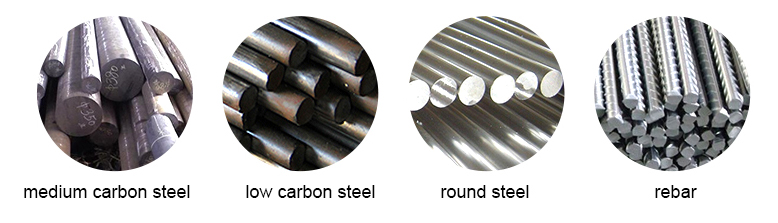

Electric rebar bender is a portable bending machine for carbon steel bar, round steel, rebar, etc. It can be operate it by hand or place it on table. Best quality with ideal price. Industrial/commercial use.

Specification

| Model |

T-HRB-25 |

| Rated Voltage |

110V, 220V |

| No-Load Power |

1300W, 950W |

| Bending Range |

Ф4-Ф25mm (1 inch) |

| Bending Angle* |

0~130° |

| Bending Speed |

2.5~3s |

| Machine Length |

660mm |

| Packing |

iron box |

| Weight |

22 kg |

*Note: Bending 90°, rebar diameter should be 16-25mm. Rebar diameter <16mm,bending angle cannot reach 90°.

Features

- Electric rebar bender is a handheld rebar bending tool, high power, high strength, high efficiency and strong corrosion resistance.

- When bending work is completed or there is an error in the middle, can return piston to the starting position by manual reset button.

- Long bolt rod limits the stroke to achieve precise bending.

Electric Rebar Bender Structure Diagram

Electric Rebar Bender Applications

Rebar Bending Effect Diagram

Tips: Working principle of the electric rebar bender cutting mechanism.

A central spool and spring are installed in the middle of cut-off piston. When idling, due to the action of spring, center spool will leave the middle oil hole of hydraulic cylinder, and high-pressure oil will flow back to tank through the eccentric shaft. When using the electric rebar bender cutting rebar, a human force pushes piston, it make central valve column to block the central hole of hydraulic cylinder. At this time, high-pressure oil from plunger pump enters hydraulic cylinder through the oil valve, generating high pressure and pushing piston to move.

Piston of the electric rebar bender drives cutter to cut steel bars. At this time, the reverse thrust of pressure spring is greater than the pressure in hydraulic cylinder, the spool returns to its original position. Hydraulic oil flows back to oil tank along the oil path of center oil hole. The return stroke of cutting piston is realized by rebound force of the leaf spring.