Automatic screw feeder is a mini machine for storaging and feeding screw. When using, take out the screw by digging. Screw feeder has functions of individual counting and total counting. Quantity of screw feed can be set arbitrarily within the range of 0~9999.

Specification

| Model |

T-ASF-AT1050 |

| Shell Material |

baking varnish |

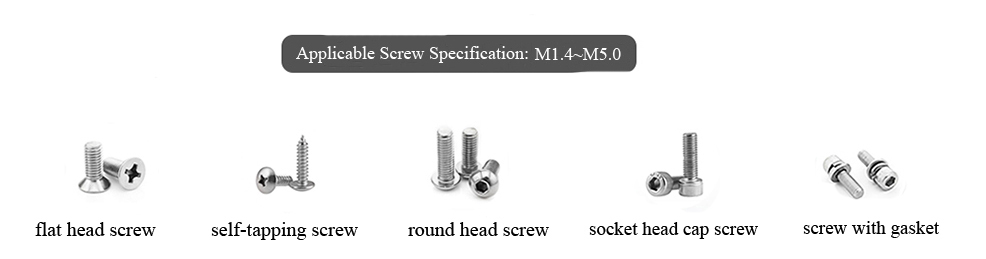

| Applicable Screws Spec. |

M1.4, M1.7, M2.0, M2.3, M2.6, M3.0, M3.5, M4.0, M4.5, M5.0 |

| Screw Head Shape |

JLS: dish head, tightening, pressure, UH head (countersunk or oval countersunk), with or without washer

JCIS: type 1, 2, 3, 4 dish head |

| Screw Thread Length |

≤20mm (without screw head thickness) |

| Supply Speed |

60-180 pcs/min |

| Input |

AC 100-240V (50/60Hz) |

| Output |

12V/2.0A |

| Capacity |

200~220cc |

| Weight |

2.63kg |

Features

- Counting function of the automatic screw feeder can be switched automatically/manually, and when the number reaches preset value, it will automatically alarm and stop.

- Applicable screws range for the automatic screw feeder is wide, and the track can be adjusted freely according to screws size.

- Screw blanking time and vibration time are independently provided by PCB to achieve operational efficiency. The PCB is protected by casing to prevent short circuits caused by the accumulation of screws. When jam occurs, the fault is automatically removed.

- Vibration motor in the automatic screw feeder has a shaft eccentric wheel fixing plate, which can prevent the motor shaft from reaming and damaged when the eccentric vibration occurs.

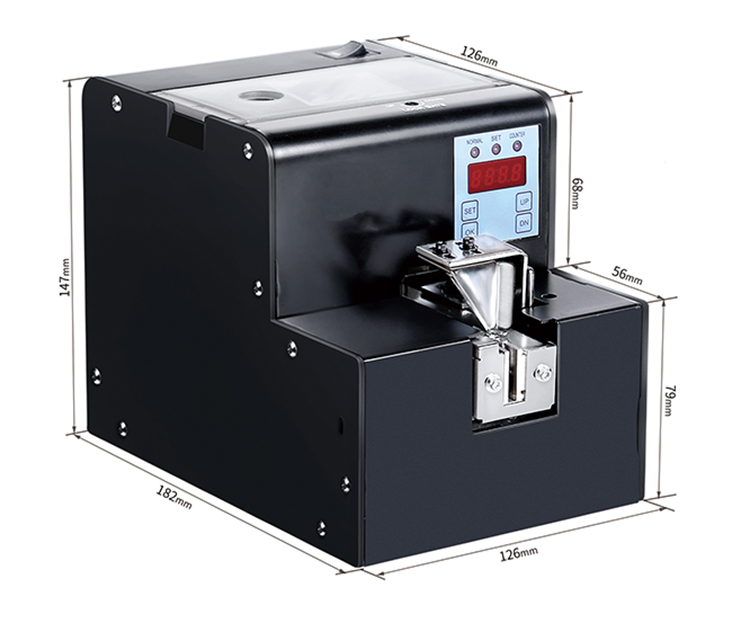

Automatic Screw Feeder Dimension Drawing

Automatic Screw Feeder Usage Method

- Select the screw vertically downwards.

- Pull out the screw forward horizontally

- Don’t pull out upwards to avoid the screws touch the guide rail and falling.

Applicable Screws

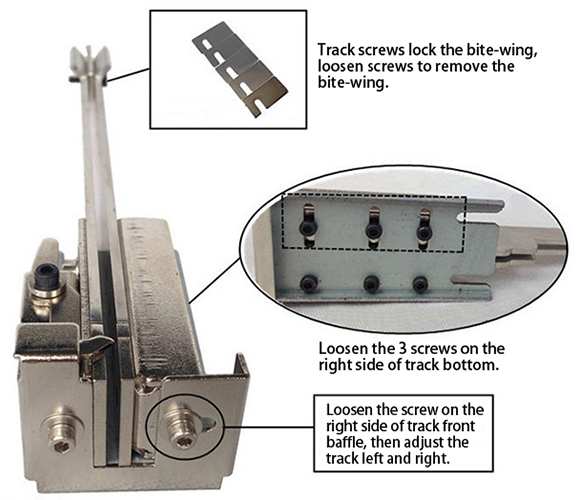

Track Adjustment for Automatic Screw Feeder

- Loosen the screw that locks the bite-wing and remove the bite-wing.

- Loosen the 3 screws on the right side of track bottom. (Just make the track loose, no need to unscrew screws completely)

- Loosen the screw on the right side of track front baffle, then adjust the track left and right.

- Adjust the track width according to size of the screws used. Bite-wing should be adjusted to be about 0.5mm larger than the thickness of thread (make screws can go back and forth smoothly).

- Lock the bite-wing. Keep the width between the bite-wing and track front baffle consistent, and then tighten screws on the right side of the front baffle and the screws on the track bottom.

Tips: What is an automatic screw feeder?

Screw feeder, also known as screw arranging machine, is a small automatic equipment that can arrange screws in a row to improve work efficiency. Automatic screw feeder is mainly to simplify the manual operation process in traditional screw locking process and reduce the labor intensity.

Simply put, working principle of automatic screw feeder is to put scattered screws into the screw storage bin. Then use fan blades to rotate, arrange screws on the track, and transport them to the discharge port along track. When the screw is in place, feeding will stop. In this way, it is convenient for electric screwdriver bit or air screwdriver bit to suck screws and then drive it into the corresponding screw hole position.

Automatic screw feeder simplifies the traditional locking action and improves production efficiency. It is widely used in electronics industry. Compared with traditional screw trays, automatic screw feeder can save 1.5 seconds in extracting each screw. Therefore, production efficiency can be increased by 4 times.