The hydraulic punching machine is a portable hole puncher driven by hydraulic system. It must matched with hydraulic pump for use, applicable materials are iron sheet and copper busbar.

Specification

| Model |

T-CH-18D |

T-CH-18F |

| Output Force |

10 Ton |

5 Ton |

| Max. Punching Thickness |

Iron Sheet |

6mm |

4mm |

| Copper Busbar |

6mm |

4mm |

| Throat Depth |

40mm |

35mm |

| Size |

320*140*230mm |

320*140*230mm |

| Weight |

4.6 kg |

3.3 kg |

| Default Punching Dies Configuration |

Φ 10.5mm, 1 set (includes upper die and lower die) |

| Optional Punching Dies |

Φ 6.5mm, 8.5mm, 12.5mm, 14.5mm, 16.5mm, 18.5mm |

Note: The hydraulic punching machine needs to be used with a pump. (Hydraulic hand pump T-CP-180, T-CP-700 or hydraulic electric pump T-HHB-700A is recommended).

Features

- Portable hydraulic punching machine is used in punching holes for metal materials such as aluminum and copper busbars. It is a special punching tool for busbar installation.

- Fast punching speed, accurate positioning and no offset.

- Hydraulic punching can eliminate the chips generated during mechanical drilling, provide a safe and clean working environment.

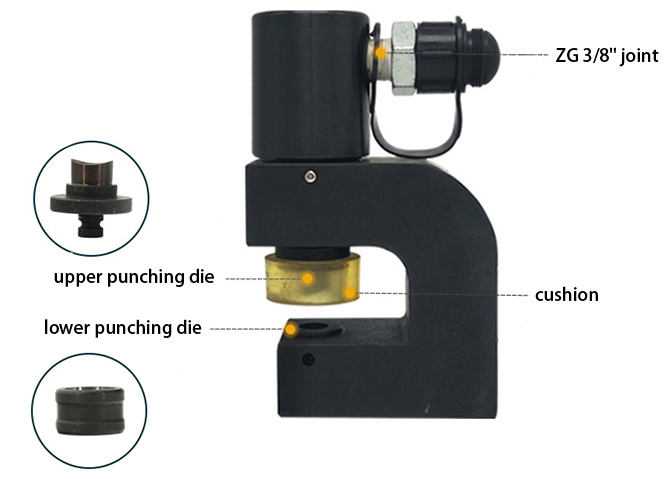

Structure Diagram of Portable Hydraulic Punching Machine

- ZG 3/8” joint: The thread is clear, not easy to wear, joint is firm, with a plastic protective sleeve, not easy to oxidize.

- The upper punching die: Commonly known as the male die, it is installed inside the cushion, diameter of punching hole is 6.5-18.5mm (the die specification is optional)

- The lower punching die: Commonly known as the female die, the mold must correspond up and down. The distance from the center of die to the edge is the throat depth.

- Cushion: auxiliary material withdrawal. After punching on metal materials, the male die can be quickly reset under the action of cushion and active spring.

Tips: What is a hydraulic punching machine?

Hydraulic punching machine is a category of punching machine, including 2 types: split hydraulic punching machine and integrated electric hydraulic punching machine.

Split hydraulic punching machine is composed of a hand pump or an electric pump and a hydraulic punching head. The oil hose is connected by hydraulic quick connector. It has the advantages of sealing, reliability, speed, no directional restriction during operation, and convenient assembly and disassembly.

The integrated electric hydraulic punching machine is composed of a pump and a punching head, without hydraulic tubing, so it is more compact in design and structure. According to the type of motor, it is divided into brush punching machine and brushless punching machine. Brushless electric hydraulic punching machine has the characteristics of a brushless motor and has obvious advantages in use and life.