Electric jig saw is a multi-function hand-held jig saw, can cut straight lines, oblique lines and curves. Cutting materials are metal and wood, including wood board, thin iron sheet, plastic, etc. It features small size, compact structure, adjustable saw blade swing and 4 pendulum action settings.

Specification

| Model |

T-JS007 |

T-JS009A |

| Rated Voltage |

230V 50Hz, 240V 60Hz |

| Input Power |

600W |

650W |

| Rated Current |

2.6A, 2.5A |

2.8A, 2.7A |

| No-Load Speed |

0-3,000 rpm |

| Cutting Capacity |

Wood: 3.15 inch (80mm)

Steel: 10mm |

| Bevel Cutting Range |

-45°~0°~45° |

| Stroke Distance |

24mm |

20mm |

| Weight |

3 kg |

Electric Jig Saw Dimensions Drawing

| T-JS007 |

T-JS009A |

|

|

Electric Jig Saw Details Diagram

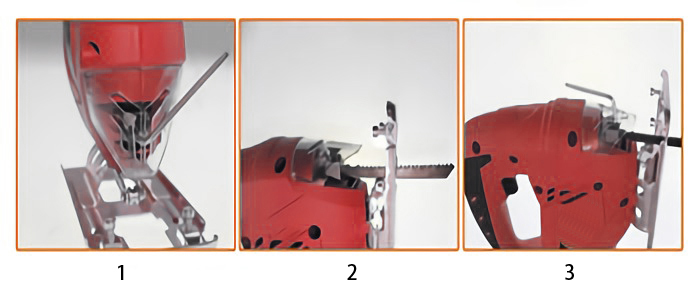

Saw Blade Installation for Electric Jig Saw

- Use a hexagonal wrench to unscrew the screw.

- When installing saw blade, remember to make it close to the groove of screw below.

- Tighten the screws with hexagonal wrench.

Guide Ruler Installation for Electric Jig Saw

- Unscrew the hexagon socket screws.

- Put guide ruler through the positioning hole and tighten hexagon socket screw.

Tips: Use electric jig saw for straight cutting.

First use a ruler to draw a straight line on sheet material. Make the base of electric jig saw close to board surface, hold it by hand and control the stroke direction of jig saw. If the cutting line is completely parallel to one side of the sheet material, a metal guide track can be used to assist.

When operating, make the large end of guide track close to the reference edge of sheet material, and insert the other end into the reserved hole on jig saw base. According to the required width of sheet material, insert guide track to the corresponding scale. To calculate the corresponding position of guide track to saw blade, that is, the middle of base, not one side of base. Finally, use two hexagon socket screws to lock guide track.

As long as one side of guide track is close to the edge of sheet material when sawing, a straight wood strip can be sawn. If it needs to finish machining and create edges for sheet material, leave a few millimeters more when setting numerical scale.