Tamping Rammer

Jumping Jack Tamping Rammer, 10kN, 2.2kW

Jumping Jack Tamping Rammer, 10kN, 5/5.5/6.5HP

Jumping Jack Tamping Rammer, 12kN, 5/5.5/6.5HP

Jumping Jack Tamping Rammer, 13kN, 5/5.5/6.5H

Jumping Jack Tamping Rammer, 14kN, 5/5.5/6.5H

Jumping Jack Tamping Rammer, 15kN, 4HP

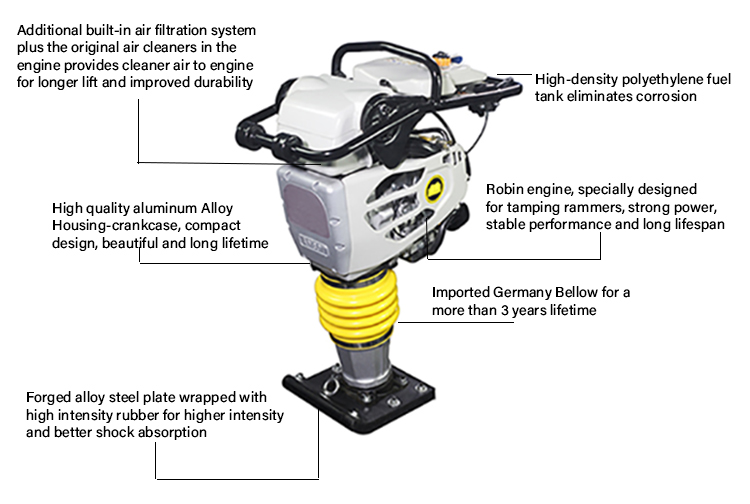

Good price tamping rammers (jumping jack tampers) on Tool.com store for sales, powerful construction tools ideal for compacting sands, granular soils, mixed soils, gravel, and crushed aggregate in narrow or enclosed areas. Rammers come in 10kN to 14kN different impact force, 5/5.5/6.5HP single sylinder, 4-stroke, air cooled petrol engines from Honda or Robin to ensure that our jumping jack tampers will need yous specific compaction needs. View the product list below and buy best tamping rammer features easy starting, low-noisy operation, low maintenance and reduced fuel consumption.

Jumping jack tamping rammer

Jumping jack tamping rammer is a compaction machine that uses impact and vibration to compact backfill in layers. Gasoline tamping rammer, also known as firepower ramming, is used for tamping and leveling asphalt gravel, concrete and clay. It is especially suitable for the construction of buildings, grounds, courtyards, roadbeds, bridge piles, trenches, fields, and narrow sites. The jumping jack tamping rammer overcomes the shortcomings of electric rammers that need to find a power source, and solves the trouble of not working without power, especially overcoming the unsafe factors of electric rammers on the human body, and can be competent for construction tasks that large and medium-sized machinery cannot complete. The jumping jack tampper machine adopts a fully enclosed oil-lubricated impact system, which has a compact structure, large jumping amplitude, strong impact force, low maintenance cost, and can reduce operator fatigue.

The jumping jack tampper machine is suitable for compaction of backfilled soil and gravel in highway construction, compaction of road foundation soil for municipalities, airports, ports, and stations; compaction of backfilled soil around underground waterways, underground electrical pipelines, and gas pipelines, and narrow sites construction etc.

Working principle

The jumping jack tamping rammer is made according to the principle of a two-stroke internal combustion engine. There are two pistons in the cylinder, the upper piston is the internal combustion piston, and the lower piston is the buffer piston. The lower part of the cylinder is equipped with a rammer with an inclined bottom surface, so that the vertical axis of the cylinder is inclined forward. The upper piston rod protrudes from the through hole in the middle of the cylinder top cover, and the lower piston rod protrudes from the lower end of the cylinder and is integrated with the rammer. The cylinder and the rammer are tensioned by springs, and handrails are provided to control the forward direction of the jumping jack tamping rammer. Under the action of the explosive force of the combustible mixture, the impact ram jumped forward and upward from the ground, and under its own weight, it fell to the ground and rammed the soil. The jumping jack tamping rammer leaped and fell, and the fuselage moved forward step by step.

Important design

- Impact spring. Jumping jack tamping rammers have high requirements for impact springs, and spring steels are required to have high fatigue strength, otherwise they will easily yield due to fatigue and lose elasticity or even break. At present, due to cost considerations, most of the spring materials of electric tamping rammers are ordinary spring steel, and there is only a single set of springs, so the impact force and impact frequency of electric tamping rammers are not high, and the springs are easy to break.

- Dynamic balance design. The movement of the jumping jack tampper machine is mainly vertical high-frequency linear reciprocating motion, and the height of the machine is high, so the jumping jack tampper machine has a high requirement for the overall dynamic balance of the machine, and special dynamic balance design and testing are required. Otherwise, the machine will be unstable and difficult to control, which greatly increases the labor intensity of the operator.

Features

- The stroke is adjustable, which can compact different soil and asphalt roads.

- The large closed air filter system is easy to clean and the engine is not easily damaged.

- The special muffler cover can reduce the noise generated by the engine and the bottom plate to the operator.

- Shock-absorbing guide handle can reduce operator fatigue.

- The bottom plate made of ductile iron has a longer service life.

- Fully sealed, splash-type lubrication impact system to ensure reliable lubrication of parts.

Troubleshooting

1. The cylinder block is locked, the bearing is locked or even damaged.

- The machine lacks lubrication.

- Solution: Before using the new machine, add 0.6 liters of No.10 lubricating oil to the body. Change the oil once after 30 hours of continuous operation, and then change it every 100 hours.

2. The power is normal and the machine does not work.

- The piston body is broken.

- The spring card falls off.

- The bearing is locked or damaged.

- The gear is damaged.

- (Electric) spline or spline shaft is damaged.

- (Internal combustion type) The clutch spring is disconnected and the clutch does not work.

- The (internal combustion type) oil seal is damaged, and lubricating oil enters the gear shaft, causing the clutch to slip.

3. The jumping jack tampper machine is leaking oil.

- The gasket is damaged and aged or the fuel tank is damaged.

- The oil window or oiling screw is loose and the seal is not tight.

- When repairing, select repair or replacement according to the specific situation.

4. Weak bounce.

- Adding too much or too little lubricating oil causes the spring resistance to be too large and cannot expand and contract normally.

- The spring is aged or shortened.

- The spring pressure plate becomes thin after wear.

- The added lubricating oil does not meet the standard.

5. Torsion of crankcase.

The upper and lower hoops are loose.

6. The ramming machine has indirect jumps and stops working after several jumps.

- The spring is broken.

- The piston body is broken.

- The bearing is damaged.