A level is a measuring tool that establishes a horizontal line of sight to determine the height difference between two points on the ground. Its main components include the telescope, tube level (or compensator), vertical axis, base, foot screw. According to the structure, the level is divided into micro-tilt level, automatic compensated level, laser level and digital level (also known as electronic level). According to accuracy, it can be divided into precision level and ordinary level.

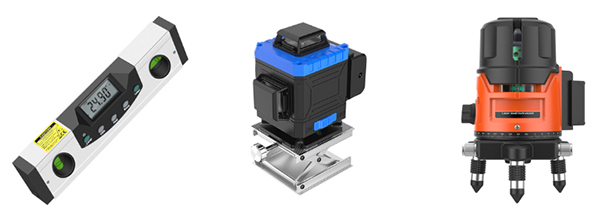

Automatic compensated level

Automatic compensated level is a level that obtains horizontal sight line by means of automatic compensator. Its main features are: When the line of sight is slightly tilted, the compensator moves the telescope relative to it under the action of gravity, so that the scale reading when the line of sight is level can be automatically and quickly obtained. The basic principle of compensation is: When the line of sight of the telescope is horizontal, the image point ZO formed by the object point P on the level ruler at the same height as the principal point of the objective lens should fall on the cross-hair intersection Z. When the telescope is tilted by a small angle α to the horizontal, the cross-hair intersection point Z moves upward, but the image point Z0 is still in the original position, which produces a reading difference Z0Z. When it is very small, it can be considered that the ZOZ spacing is α×f (f is the focal length of the objective lens). At this time, a compensator can be installed at the K point in the optical path to produce a refractive angle β. Under the condition that αxf=B×S0 (S0 is the distance from the compensator to the center of the crosshair, that is, KZ), the image Z0O falls on the Z point. Or, the reticle can be made automatically swing the instrument in the opposite direction, and the intersection point Z of the reticle falls on the Z0 point.

For example, when light refraction is not used but translation is used in the optical path, as long as the translation amount is equal to ZOZ, the crosshair intersection Z will fall on the image point Z0. This can also achieve the purpose of Z0 and Z overlap. The automatic leveling compensator can be divided into movable objective lens, movable crosshair and suspended prism according to the structure. The compensation device has a “pendulum”. When the line of sight of the telescope is slightly tilted, the compensation element will swing. In order to stabilize the swing of the “pendulum” as soon as possible, an air damper or magnetic damper must be installed. This kind of automatic compensated level has the characteristics of higher work efficiency and stable accuracy than the micro-tilt level, especially in areas with windy and large temperature changes.

Laser level

A laser level is a measuring tool that uses a laser beam instead of manual reading. It guides the laser beam emitted by the laser into the telescope tube to emit a horizontal laser beam along the collimation axis. By using the monochromaticity and coherence of the laser, a glass or metal sheet with a certain shading pattern can be assembled in front of the telescope objective lens, that is, a zone plate, to cause diffraction interference. After focusing by the telescope, within the focusing range of the zone plate, a bright and fine cross-shaped or circular laser spot can be obtained, so as to collimate the target more accurately. If the front and rear leveling rulers are equipped with photoelectric receiving targets that can be tracked automatically, leveling can be performed. In the construction survey and the assembly of large components, a laser level is often used to establish a horizontal plane or horizontal line.

Electronic level

Electronic level is also called digital level. It is developed on the basis of the automatic compensated level. The digital level is the most advanced level. With a special bar code leveling ruler, the built-in digital imaging system in the instrument can automatically obtain the bar code reading of the leveling ruler, eliminating the need for manual reading. This instrument can greatly reduce the labor intensity of surveying and mapping operations, avoid man-made subjective reading errors, and improve measurement accuracy and efficiency. It uses a bar code ruler. The bar code patterns of the scale codes of different manufacturers are different and cannot be used interchangeably. Before 2013, sighting and focusing still needed to be done visually. After collimating and focusing manually, the bar code of the ruler is imaged on the telescope differentiation plate for visual observation. On the other hand, through the spectroscope of the telescope, the ruler bar code is imaged on the photoelectric sensor (also called the detector), that is, the linear CCD device, for electronic reading. Therefore, if the traditional leveling ruler is used, the electronic level can be used like an ordinary automatic compensated level. However, the measurement accuracy at this time is lower than that of electronic measurement. Especially for the precision electronic level, because there is no optical micrometer, if it is used as an ordinary automatic leveling level, its accuracy is lower.