The laser level is a measuring machine widely used in the construction industry for measuring the level. It has the advantages of high accuracy, convenient use, fast and reliable, and can be used in surveying, large-area site surveying, floor level marking, settlement observation, etc. Tool.com will explain in detail the operation and control steps of the laser level for wholesale online.

1. Open the tripod, keep its height near the chest, keep the head of the frame roughly level, step on the toes into the soil, and then use the connecting screw to connect the equipment to the tripod.

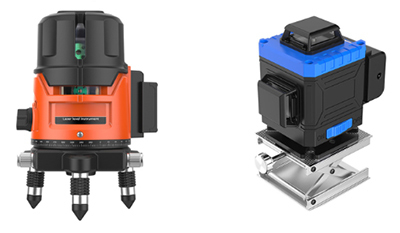

2. First of all, we must understand the names and functions of the parts of the laser level and be familiar with their use. The laser line meter is made by fixing a laser device on the tube of an ordinary level telescope. The laser device consists of a nitrogen-neon laser and a prism light guide system. The laser line meter is first installed according to the operating method of the level. First, level the instrument and aim at the target, connect the laser power supply and turn on the power switch. After the laser is started normally, adjust the working current to about 5mA. At this time, there will be the strongest laser output, and the target will get a bright red light. When the light spot is not clear enough, you can adjust the spiral until it is clear. Then, it is required to install the zone plate, the light spot can be changed into a cross-shaped red line, which can improve the accuracy of reading.

3. Rotate the two leg screws in opposite directions to make the bubble of the circular level move to the center, and then rotate the other leg to move the bubble to the center position.

4. Turn the eyepiece focusing screw to make the crosshair clear. Rotate the laser level device, use the front sight and sight to aim the level ruler, tighten the brake screw (there is resistance in the hand). Turn the micro-motion screw to make the leveling ruler image at the intersection of the crosshairs. The laser level can measure whether the surface is uneven or scratched. When the imaging is not very clear, you need to rotate the light spiral to eliminate parallax and make the target clear.

5. Observe in the bubble window of the leveling pipe, and turn the slightly inclined screw to see if the penumbra of the leveling bubble matches. If it matches, the line of sight is in a smooth state. At the same moment, it is necessary to immediately read meters, decimeters, centimeters, and estimated millimeters on the level ruler, that is, read out four significant figures. The laser marking instrument uses a semiconductor pump laser as the light source. After a set of lenses are integrated, it can emit a point-shaped light source with high collimation. After being scattered by a special ridge, a light with uniform brightness can be formed. Due to the special design of the prismatic brocade to diffuse the light, this effectively avoids the shortcomings of two light intensity and weak light intensity caused by ordinary cylindrical lenses to diffuse light.

6. Safety tips of laser level

- Do not stare at the laser beam.

- Laser marking output is located at the output hole.

- Do not disassemble the laser leveling machine for inner maintenance, and only the authorized maintenance center is allowed to do that.

- The 8 line rotary green laser level and 16 line rotary green laser level for wholesale on Tool.com meets the radiation safety standard, so the customers can buy with assurance.